973 Track Loader

- new - Products

- 973 Track Loader

At a glance data:

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

Overview

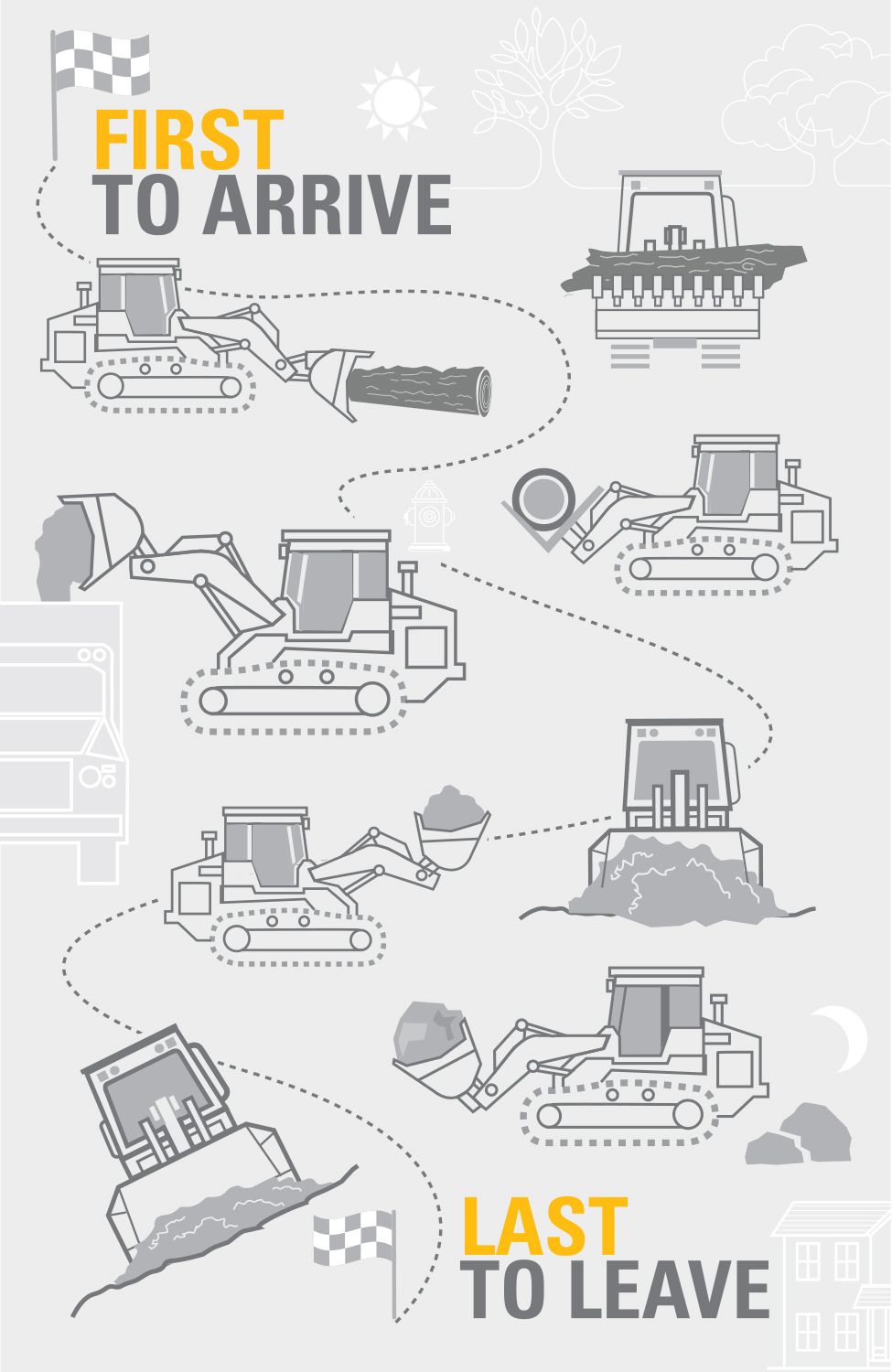

Save money and transport time with one rugged machine that does it all – land clearing, digging, grading, truck loading, slope work and more. Crawler loaders give you lower ground pressure and better traction so you can start the job sooner, and work longer, in all kinds of underfoot conditions. Cat® Track Loaders give you all this, plus outstanding performance and fuel efficiency.

Engine

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

Emissions:

Meets U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 emission standards or Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA.

Note (1):

Cat U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)*; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Cat engines meeting Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to U.S. EPA Tier 3/ EU Stage IIIA, are compatible with diesel fuel blended with the following lower-carbon intensity fuels up to: 100% biodiesel FAME (fatty acid methyl ester)**; 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (For use of blends higher than 20% biodiesel, consult your Cat dealer). **For use of blends higher than 20% biodiesel, consult your Cat dealer.

Note (2):

Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions Module (when equipped) and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture.

Note (3):

Machine Build Number 12A

Weights

Operating Weight:

65901lb

Service Refill Capacities

Fuel Tank:

119gal (US)

DEF Tank:

9.2gal (US)

Standard

Operating Weight:

65901lb

Width of Standard Shoe:

27in

Ground Pressure:

9.5psi

Low Ground Pressure (LGP)

Operating Weight:

71218lb

Width of Standard Shoe:

33in

Ground Pressure:

8.4psi

Waste Handler

Operating Weight:

67164lb

Width of Standard Shoe:

27in

Ground Pressure:

9.7psi

Dimensions

Overall Machine Length*:

295in

Machine Height - Top of Cab:

138.2in

Overall Width - Without Bucket:

111.6in

Hinge Pin Height at Maximum Lift:

166.1in

Note:

*With General Purpose bucket with bolt-on full edge

Undercarriage

Track on Ground:

115.3in

Track Rollers/Shoes - Each Side:

40

Buckets

Capacity - General Purpose:

4.2yd³

Capacity - Multi-Purpose:

3.9yd³

Capacity - Performance Series:

5yd³

Capacity - Landfill:

6.4yd³

Capacity - Slag:

3.9yd³

Width - General Purpose:

118.5in

Width - Multi-Purpose:

116.6in

Width - Performance Series:

118.7in

Width - Landfill:

118.5in

Width - Slag:

116.5in

Note:

Additional buckets and work tools available. Please consult with your Cat dealer.

Air Conditioning System

Air Conditioning:

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.1 kg of refrigerant which has a CO2 equivalent of 1.573 metric tonnes.

Standard Equipment

note

- Standard and optional equipment may vary. Consult your Cat dealer for details.

power train

- Cat C9.3B Diesel Engine

- Hydraulic demand fan

- Hydrostatic transmission

- Load sensing implement pump

- Modular cooling system

operator environment

- 12V power outlet and 5V USB port

- Adjustable armrests

- Configurable implement levers

- Full-color 254 mm (10 in) touchscreen display with integrated rear camera, machine slope indicator, bucket angle indicator

- Grab handle on dash

- Heat/Air conditioning

- Integrated rearview HD camera

- Lights - 4 halogen

- Standard cab with one sliding side window and four halogen lights: two facing forward, roof mounted, two facing rearward, integrated in the air conditioner unit

- 24V radio ready

- Storage areas throughout cab

- Lunch box storage with strap holder

cat technology

- Slope Indicate

- Product Link™ ready

undercarriage

- HDXL track

- Oscillating track roller frames

buckets

- Pin-on

- Cat Advansys™ bucket tips/Ground Engaging Tools

service and maintenance

- 4 x 2 Easy tie-down points on chassis

- Metallic fuel tank

- Ecology drains

- Ground level service center

- Hinged radiator guard and swing out fan

- Shovel holder

Optional Equipment

note

- Standard and optional equipment may vary. Consult your Cat dealer for details.

power train

- Cat C9.3B diesel engine with engine-mounted aftertreatment to meet U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V, China Nonroad Stage IV, Japan 2014 emission standards

- Cat C9.3B diesel engine to meet Eurasian Economic Union Stage IIIA, UN ECE R96 Stage IIIA emission standards, equivalent to Tier 3/Stage IIIA

operator environment

- Communication radio ready - FM

- Deluxe seat

- Joystick or two-lever implement controls

- Joystick or V-lever-and-pedal steering controls

- LED flashing beacon

- Lights - 2 LED front/bottom of cab, access light

- Lights - 8 LED

- Premium seat

- Radio AM/FM Bluetooth

- Radio AM/FM/DAB+ Bluetooth

- Radio AM/FM/Sirius XM Bluetooth

- Deluxe cab package with two sliding side windows and eight LED lights: four roof-mounted facing forward, two facing rearward and two facing side integrated in the air conditioner unit

- Steel Mill cab with thermal protection, all sealed windows, windshield and front light protection, eight halogen lights: four facing forward, two facing sideways, two facing rearward integrated into air conditioner unit

cat technology

- Remote Flash/Remote Troubleshoot

- Product Link, Cellular

- Product Link -- Dual Cellular/Satellite

- Cat Payload

- Grade control mast

undercarriage

- Single, Double or Triple Grouser track shoes

- Waste or Low Ground Pressure (LGP) undercarriage

- Steel Mill undercarriage

buckets

- Fusion quick coupler

- General Purpose bucket

- Landfill bucket

- Multi-Purpose bucket

- Performance bucket

- Slag bucket

service and maintenance

- Cold weather package

- Fast fuel fill

- Insulated metallic fuel tank (Steel Mill)

- High Speed oil change

- Hydraulic reversing fan

- Hydraulic tilt cab

- Refueling pump

attachments

- Bumper

- Counterweights

- Multi-shank ripper

- Ripper hitch

- Ripper-ready rear hydraulics

- Striker bar box

special arrangements

- Low Ground Pressure (LGP) Arrangement

- Waste Handler

- Ship Hold Arrangement

- Steel Mill Arrangement

953 Track Loader

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

963 Track Loader

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

Similar Products

953 Track Loader

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

963 Track Loader

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp

973 Track Loader

Flywheel Power:

275hp

Model:

Cat® C9.3B

Net Power - ISO 9249/SAE J1349:

275hp

Net Power - ISO 9249 (DIN):

279mhp