988 Wheel Loader

- new - Products

- 988 Wheel Loader

At a glance data:

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

Overview

Cat® Large Wheel Loaders are designed with durability built in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to move more material efficiently and safely at a low cost per ton. Introduced in 1963, the 988 has been an industry leader for 60 years. Focused on helping our customers succeed, we have continued to build upon each new series. The 988 continues our legacy of reliability, performance, safety, operator comfort, serviceability, and efficiency.

Engine

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

Peak Power Speed:

1500/rpm

Rated Speed:

1700/min

Emissions:

U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards, Brazil MAR-1 and China Nonroad Stage IV emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA, and U.S. EPA Tier 2 and EU Stage II

Bore:

5.7in

Stroke:

7.2in

Displacement:

1105.0in³

Peak Torque - 1,200 rpm:

2230lb/ft

Torque Rise:

58.0%

Operating Specifications

Operating Weight:

112574lb

Rated Payload - Quarry Face:

12.5t

Rated Payload - Loose Material:

16t

Bucket Capacity Range:

4.7-13 m3 (6.2-17 yd3)

Cat Truck Match - Standard:

770~772

Cat Truck Match - High Lift:

773~775

Transmission

Transmission Type:

Cat planetary powershift

Forward - 1:

4.0mile/h

Forward - 2:

7.2mile/h

Forward - 3:

12.7mile/h

Forward - 4:

21.6mile/h

Reverse - 1:

4.7mile/h

Reverse - 2:

8.3mile/h

Reverse - 3:

14.4mile/h

Direct Drive - Forward 1:

Lock-up disabled

Direct Drive - Forward 2:

7.8mile/h

Direct Drive - Forward 3:

13.9mile/h

Direct Drive - Forward 4:

24.4mile/h

Direct Drive - Reverse 1:

5.0mile/h

Direct Drive - Reverse 2:

8.9mile/h

Direct Drive - Reverse 3:

15.8mile/h

Hydraulic System - Lift/Tilt

Lift/Tilt System - Circuit:

EH- Positive Flow Control, Flow Sharing

Lift/Tilt System:

Variable displacement piston

Maximum Flow at 1,400-1,860 rpm:

153.0gal/min

Relief Valve Setting - Lift/Tilt:

4757psi

Cylinders, Double Acting - Lift, Bore and Stroke:

210 mm × 1050 mm (8.7 in × 41.3 in)

Cylinders, Double Acting - Tilt, Bore and Stroke:

269 mm × 685 mm (8.7 in × 27 in)

Pilot System:

Variable displacement piston

Relief Valve Setting - Main:

551psi

Hydraulic Cycle Time (1,400-1,860 rpm)

Rack Back:

4.5s

Raise:

8.0s

Dump:

2.2s

Lower Float Down:

3.5s

Total Hydraulic Cycle Time - Empty Bucket:

18.2s

Hydraulic System - Steering

Steering System - Circuit:

Pilot, load sensing

Steering System - Pump:

Piston, variable displacement

Maximum Flow:

71.3gal/min

Relief Valve Setting - Steering:

4351.0psi

Total Steering Angle:

86 °

Steering Cycle Times - High Idle:

3.4s

Steering Cycle Times - Low Idle:

5.6s

Air Conditioning System

Air Conditioning:

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.8 kg of refrigerant which has a CO2 equivalent of 2.574 metric tonnes.

Axles

Front:

Fixed

Rear:

Trunnion

Oscillation Angle:

13 °

Brakes

Brakes:

ISO 3450:2011

Operator's Cab

ROPS/FOPS:

ROPS/FOPS meet ISO 3471:2008 and ISO 3449:2005 Level II standards

Service Refill Capacities

Fuel Tank:

188.0gal (US)

Cooling System:

31.7gal (US)

Coolant (Validated by Test Cell Fill Quantities):

33gal (US)

Crankcase:

15.9gal (US)

Diesel Exhaust Fluid Tank:

8.7gal (US)

Transmission:

31.7gal (US)

Transmission - Validated by Test Cell Fill Quantities:

29gal (US)

Differential - Final Drives - Front:

49.1gal (US)

Differential - Final Drives - Rear:

49.1gal (US)

Hydraulic System Factory Fill:

125.5gal (US)

Hydraulic System - Tank Only:

63.4gal (US)

Sound Performance - Tier 4 Final / Stage V - Standard

Operator Sound Pressure Level (ISO 6396:2008):

73dB(A)

Machine Sound Power Level (ISO 6395:2008):

111dB(A)

Sound Performance - Tier 3 / Stage III - Standard

Operator Sound Pressure Level (ISO 6396:2008):

73dB(A)

Machine Sound Power Level (ISO 6395:2008):

112dB(A)

Dimensions (Approximate) - Standard Lift Linkage

Ground to Top of ROPS:

13.8ft

Ground to Top of Exhaust Stacks:

14.8ft

Ground to Top of Hood:

10.9ft

Rear Axle - Centerline to Bumper:

10.5ft

Front Axle Centerline to Bucket Tip:

14.0ft

Wheel Base:

14.9ft

Maximum Overall Length:

39.3ft

Ground to Lower Hitch Clearance:

1.9ft

Clearance at Maximum Lift:

11.9ft

B-Pin Height - Maximum Lift:

18.0ft

Maximum Overall Height - Bucket Raised:

24.5ft

Reach - Maximum Lift:

6.5ft

Dimensions (Approximate) - High Lift Linkage

Ground to Top of ROPS:

13.8ft

Ground to Top of Exhaust Stacks:

14.8ft

Ground to Top of Hood:

10.9ft

Rear Axle - Centerline to Bumper:

10.5ft

Front Axle Centerline to Bucket Tip:

15.3ft

Wheel Base:

14.9ft

Maximum Overall Length:

40.7ft

Ground to Lower Hitch Clearance:

1.9ft

Clearance at Maximum Lift:

13.3ft

B-Pin Height - Maximum Lift:

19.3ft

Maximum Overall Height - Bucket Raised:

25.8ft

Reach - Maximum Lift:

6.8ft

Buckets

Bucket Capacities:

4.7-13 m3 (6.2-17 yd3)

Standard Equipment

note

- Standard and optional equipment may vary. Consult your Cat dealer for details.

electrical

- Alarm, back-up

- Alternator, single 150 amp

- Batteries, dry

- Converter, 10/15 amp, 24V to 12V

- Lighting system (halogen, work lights, access and service platform lighting)

- Starting and charging system, 24V

- Jump start receptacle

- Starter lockout in bumper

- Transmission lockout in bumper

operator environment

- Graphical Information Display, displays real time operating information, performs calibrations and customizes operator settings

- Air conditioner

- Cat Vision, rear vision camera system

- Cab, sound suppressed and pressurized, integrated rollover protective structure (ROPS/FOPS) radio ready for entertainment, includes antenna, speakers and converter (12-volt 5-amp) and power port

- Controls, lift and tilt function

- Heater, defroster

- Horn, electric

- Instrumentation, gauges: – Coolant temperature – Engine hour meter – Hydraulic oil temperature – Power train oil temperature

- Light, cab, dome

- Lunchbox, beverage holders

- Mirrors, rearview (externally mounted)

- Rimpull Control System

- Seat, deluxe

- Seat belt minder

- Seat belt, retractable, 76 mm (3 in) wide

- STIC Control System

- UV glass

- Transmission gear indicator

- Vital Information Management System (VIMS) with Graphical Information Display: External Data Port, Customizable Operator Profiles, Cycle Timer, Integrated Payload Control System

- Wet-Arm wipers/washers (front and rear): – Intermittent front and rear wipers

- Lights, directional

power train

- Brakes, oil-cooled, multi-disc, service/secondary

- Case drain screens

- Crankcase guard

- Electro hydraulic parking brake

- Engine, C18 MEUI diesel, turbocharged/aftercooled

- Ground level engine shutoff

- Turbine precleaner, engine air intake

- Radiator, Aluminum Modular Radiator (AMR)

- Starting aid, ether, automatic

- Throttle lock, electronic

- Torque converter, Impeller Clutch (ICTC) with Lock up clutch (LUC), Rimpull Control System

- Transmission, planetary powershift, 4F/3R electronic control

- Manual switch and automatic fuel priming

- Cat Production Measurement ready

other

- Automatic bucket lift kickout/positioner

- Base machine price includes a rim allowance

- Hydraulically driven demand fan

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank

- Fuel tank, 712 L (188 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, steering and brake filtration/screening system

- Cat Clean Emission Module

- Oil sampling valves

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

- Rear access to cab and service platform

- Steering, load sensing

- Toe kicks

- Vandalism protection caplocks

Optional Equipment

note

- Standard and optional equipment may vary. Consult your Cat dealer for details.

power train

- –50° C (–58° F) antifreeze

- Engine oil change system, high speed, Wiggins

- High ambient cooling – software

- Cat Production Measurement

operator environment

- Cab precleaner

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with bluetooth

- LED warning strobe

- CB radio ready

- Window pull down visor

- Handrail mounted mirrors

additional equipment

- Additional counterweight

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

- Cold Weather Starting (extra starter plus two batteries), engine block heater 120V or 240V, heated fuel lines

other optional configurations

- Aggregate Handler

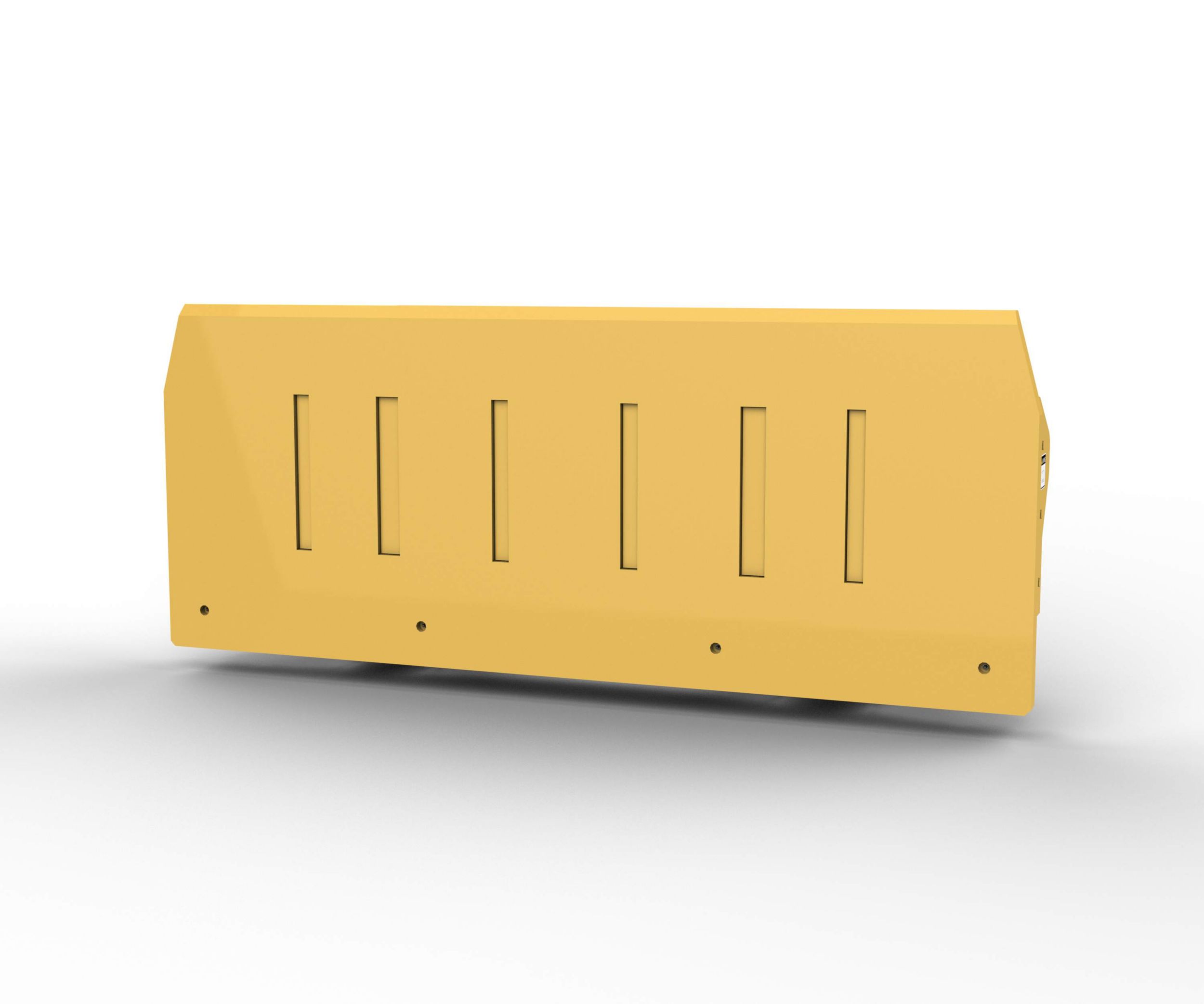

Block Handling Coupler for 988K Wheel Loaders

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

4.4m³ (5.75yd³) Iron Ore Bucket for Wheel Loaders

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

Similar Products

988 Wheel Loader

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

990 Wheel Loader

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™

988 XE Wheel Loader

Net Power - SAE J1349:2011:

538hp

Engine Power - ISO 14396:2002:

580hp

Gross Power - SAE J1995:2014:

588hp

Engine Model:

Cat® C18 ™