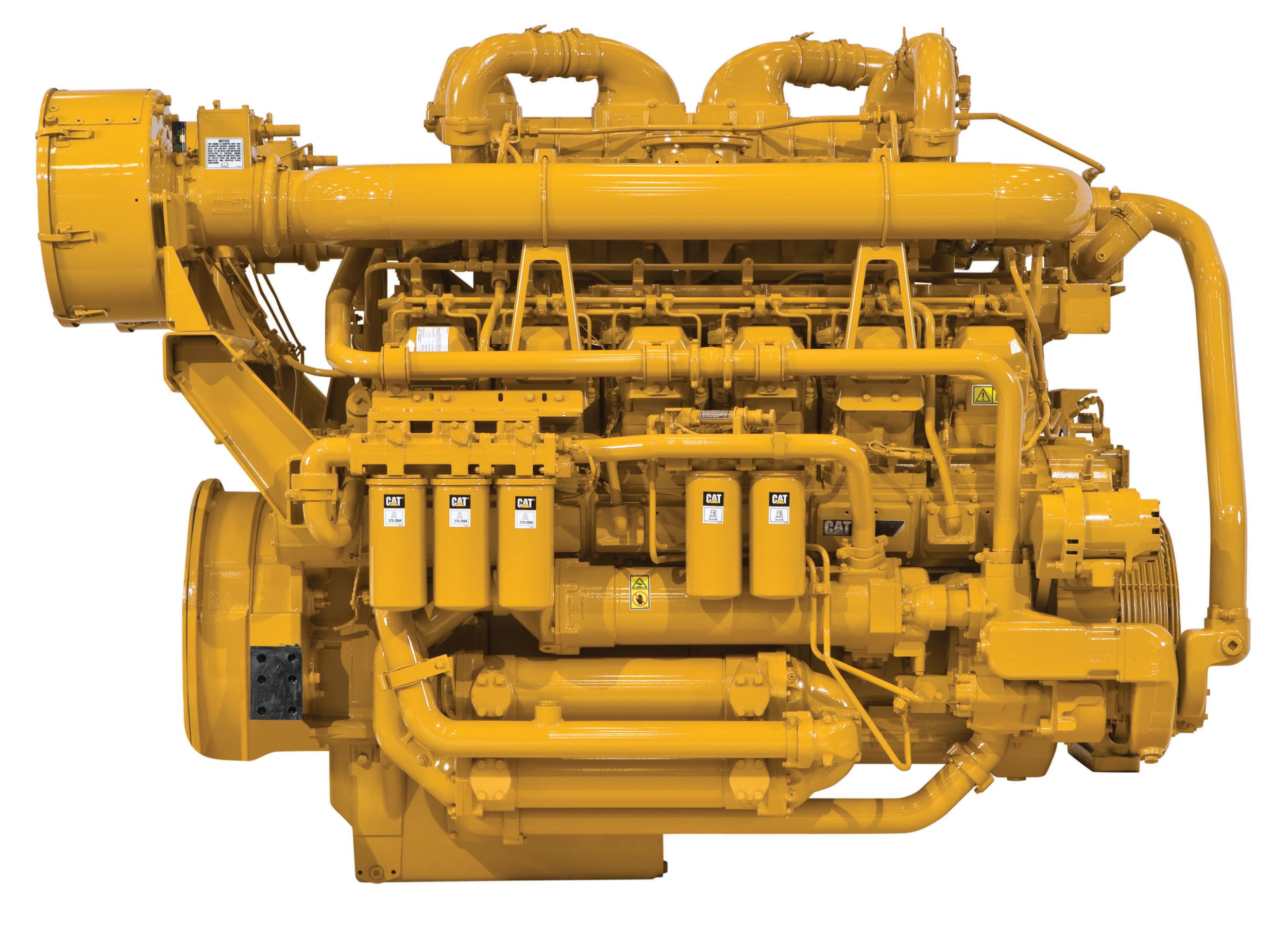

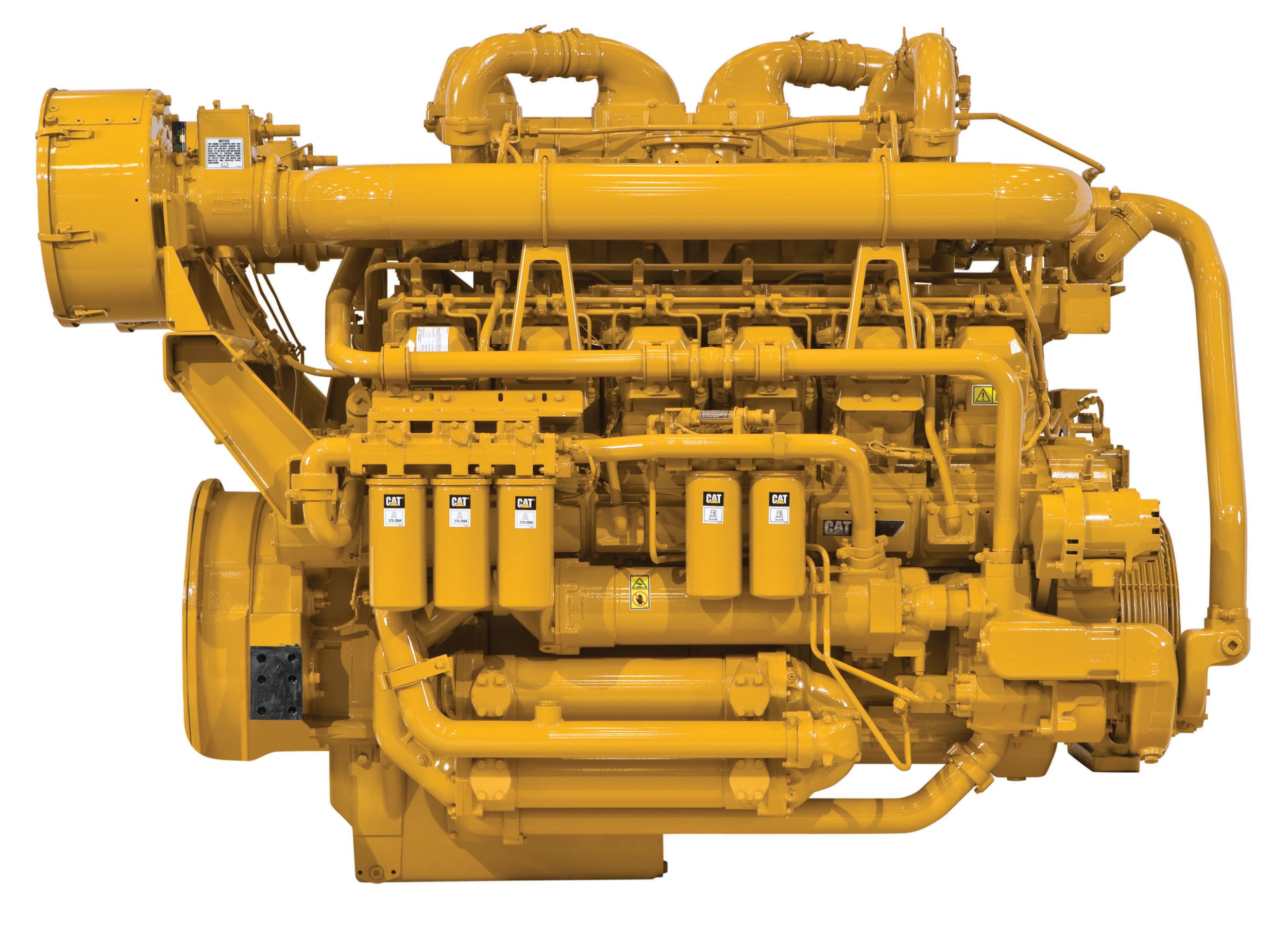

Cat® C7.1 Diesel Engine

- new - Products

- Cat® C7.1 Diesel Engine

At a glance data:

Overview

The Cat® C7.1 Industrial Diesel Engine is offered in ratings ranging from 116-205 bkW (156.2 bhp-275 bhp) @2200 rpm. These ratings meet China Stage II, U.S. EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. Industries and applications powered by C7.1 ACERT engines include: Agriculture, Ag Tractors, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Combines/Harvesters, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Feller Bunchers, Forestry, Forklifts, General Industrial, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Sweepers, Paving Equipment, Pumps, Skidders, Specialty Ag Equipment, Sprayers, Trenchers and Underground Mining Equipment.

Power Rating

Emission Standards

General

Engine Dimensions - Approximate

Standard Equipment

air inlet

- Standard air cleaners

control system

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments, flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

cooling system

- Top tank temperature 108°C (226°F) as standard to minimize cooling pack size, 50:50 water glycol mix, detailed guidance on cooling system design and validation available to ensure machine reliability

exhaust system

- Diesel particulate filter and regeneration system supplied, with a range of inlet and outlet options

flywheels and flywheel housing

- Wide choice of drivetrain interfaces, including SAE1, SAE2 or SAE3 configurations

fuel system

- Electronic high pressure common rail, ACERTTM Technology, innovative filter design to ensure maximum protection of the engine.

lube system

- Wide choice of sumps for different applications

power take off

- SAE A or SAE B flanges on left-hand side. Right- hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications, factory fitted compressors are also available.

general

- Paint: Caterpillar yellow, with optional colors available at request

Optional Equipment

Similar Products

Cat ® C0.5 Diesel Engine

Cat ® 3512 Industrial Diesel Engine