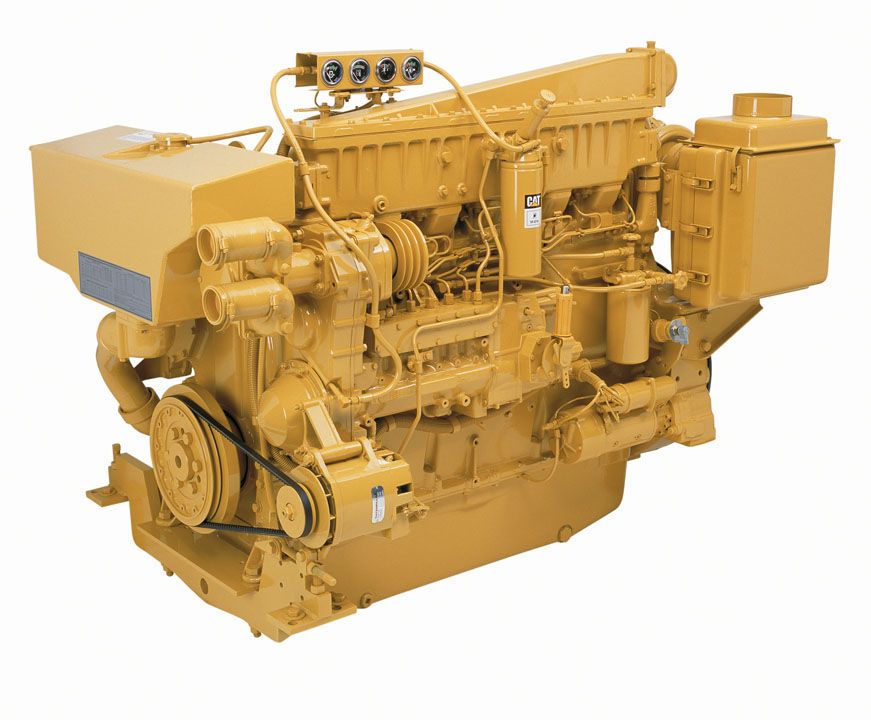

C280-12 Propulsion Engine

- new - Products

- C280-12 Propulsion Engine

At a glance data:

Power Range:

4640-5096 bhp (3460-3800 bkW)

Speed Range:

900 rpm

Emissions:

IMO II

Aspiration:

TTA

Overview

Building on the durability and reliability of the C280 engine platform, Caterpillar is pleased to offer the IMO II compliant C280 engine line. The core components are the same as the existing C280, including the latest in EUI fuel system capabilities and state-of-the-art ADEM™ A3 Electronic Control Unit (ECU) features. Caterpillar® products continue to deliver more available power while delivering outstanding fuel efficiency. You can also count on long maintenance intervals and worldwide Caterpillar parts and service availability.

Power Rating

Power Range:

4640-5096 bhp (3460-3800 bkW)

Engine Specifications

Speed Range:

900 rpm

Emissions:

IMO II

Aspiration:

TTA

Bore:

11.0in

Stroke:

11.8in

Displacement:

13546.0in³

Rotation from Flywheel End:

Counterclockwise or clockwise

Configuration:

Vee 12, 4-Stroke-Cycle Diesel

Dimensions & Weights

Dry Weight:

57276.0lb

Width:

80.0in

Length:

182.0in

Height:

134.0in

Standard Equipment

air inlet system

- Aftercooler, fresh water, corrosion resistant coated (air side)

- Air inlet shutoff

- Breather, crankcase, top-mounted

- Turbocharger, engine oil lubricated

control system

- Dual Caterpillar A-III Electronic Engine Control Modules with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp 24volt power required to drive Electronic Engine Control Modules)

cooling system

- Engine coolant water drains

exhaust system

- Dry, gas tight, exhaust manifold

fuel system

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38 degrees C)

- Fuel transfer pump (mounted on left hand side)

- Duplex fuel filters

- Electronically Controlled Unit Injectors

lube systems

- Centrifugal oil filters with single shutoff. Service side engine mounted on cylinder block inspection covers. Includes installed oil lines and single shutoff valve. Filters centrifuge bypass oil from the main lubricating oil pump. Can be serviced with the engine running.

- Oil filler and dipstick

- Valve, oil pressure regulating

- Valves, crankcase explosion relief

general

- Paint, Caterpillar yellow

- Pumps, gear driven: fuel, oil, jacket water, aftercooler/oil cooler water

Optional Equipment

engine application/design control

- Crankshaft Deflection Marks

- Extra Mounting Feet

engine package description

- Front Auxiliary Drive

- Stub Shaft Certification

air inlet system

- Air Cleaners

- Air Cleaner options

cooling system

- Auxiliary Water Pump

- Jacket Water Heaters

- Heat Recovery System

- Heat Recovery Thermostats

- De-Aerator

- Connections for Driven Equipment

- Cooling System Connection Groups

exhaust system

- Outlet Expander

- Flexible Exhaust Fittings

- Weld Flange

fuel system

- Fuel Priming Pump

- Duplex Primary Fuel Strainer

- Fuel Systems Connections

lube system

- Oil Pan Drain Valve

- Lube Connections

- Lube Oil Heater

marine society requirements

- Spray Shielding

protection system

- Monitoring System

- Turbocharger Speed Sensor

- Cylinder Pressure Relief Valve

- Oil Mist Detector

spare parts kits

- Intake and Air System

- Basic Engine

- Cylinder Head

- Fuel System

- Cooling System

- Instrumentation

- Cylinder Valve Kits

starting system

- Boost Control Valve, Pressure Reducing Valve

engine testing

- Basic System Testing

- Special Witness Test

- Customer Selected Test Points

- Marine Limit Line Test

- Propeller Demand Curve Test

service tools/ship protection/factor support

- Commissioning

- Service Tools

- Shipping Protection - Export Boxing

- AID Emblem

- Storage Preservation

Similar Products

Cat C32 Propulsion Engine (US EPA Tier 3 / IMO II)

Power Range:

4640-5096 bhp (3460-3800 bkW)

Speed Range:

900 rpm

Emissions:

IMO II

Aspiration:

TTA

Cat C32 Propulsion Engine (US EPA Tier 4 / IMO III)

Power Range:

4640-5096 bhp (3460-3800 bkW)

Speed Range:

900 rpm

Emissions:

IMO II

Aspiration:

TTA

3406C Propulsion Engine

Power Range:

4640-5096 bhp (3460-3800 bkW)

Speed Range:

900 rpm

Emissions:

IMO II

Aspiration:

TTA