310 Mini Hydraulic Excavator

- new - Products

- 310 Mini Hydraulic Excavator

At a glance data:

Print

310 Product Brochure

Cat Mini Hydraulic Excavators Product Line Brochure (North America)

Cat Mini Hydraulic Excavators Product Line Brochure (Europe)

Options And Accessories Kit Guide for Mini Hydraulic Excavators

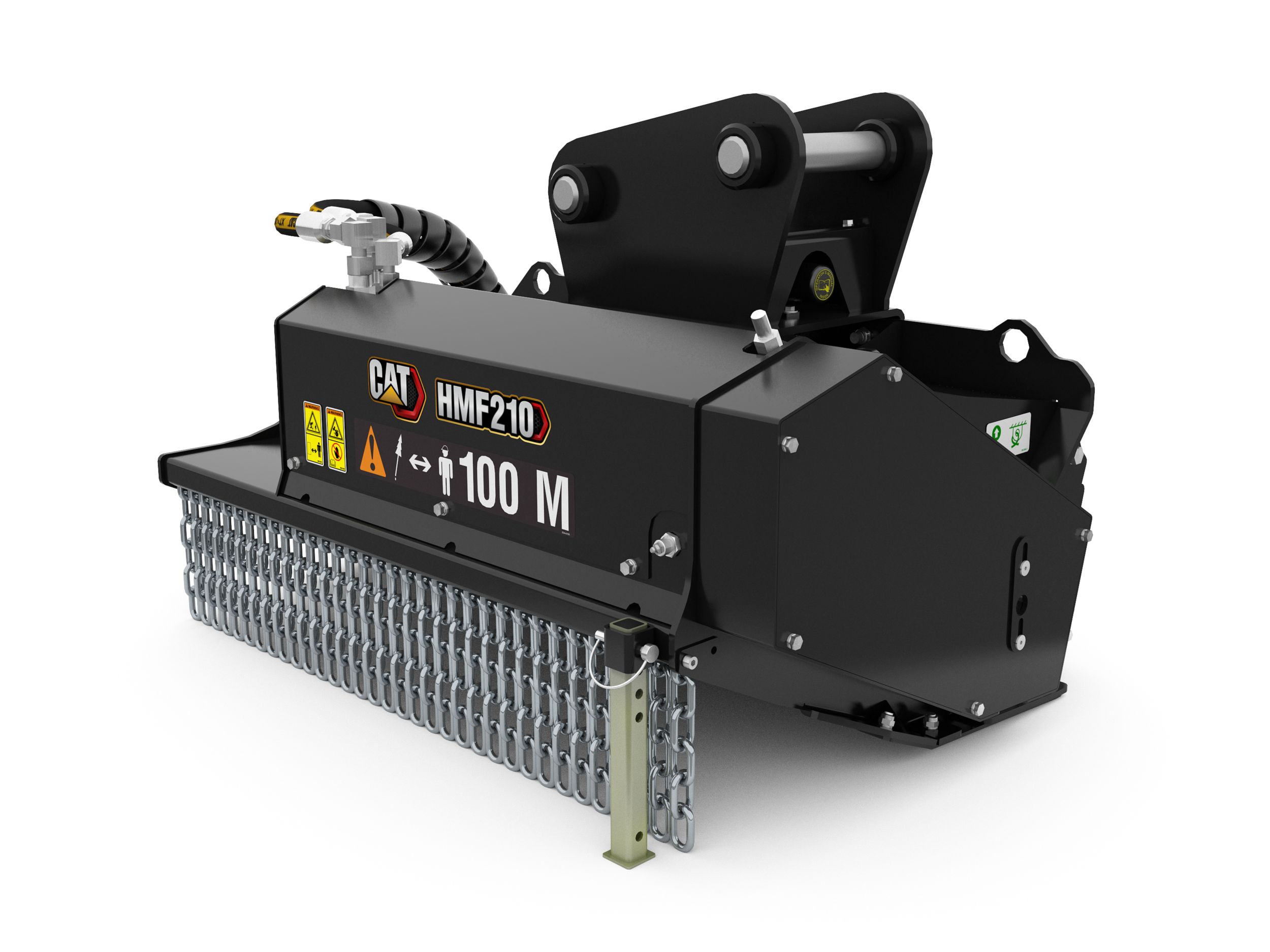

Cat Attachments for Mini Excavators Brochure

Attachment Compatibility Guide for Mini Excavators

Overview

The Cat® 310 Mini Excavator delivers maximum power and performance in a mini size to help you work in a wide range of applications.

Engine

Net Power:

69.5hp

Stroke:

4.7in

Note:

Net power advertised is the power available at the flywheel when the engine is equipped with air cleaner, exhaust system and fan.

Bore:

3.7in

Displacement:

203in³

Gross Power - SAE J1995:2014:

74.3hp

Engine Model - U.S. EPA Tier 4 Final/EU Stage V:

Cat® C3.3B

Net Power - 2,200 rpm - ISO 9249:2007, 80/1269/EEC:

69.5hp

Weights

Operating Weight:

22451lb

Minimum Operating Weight with Cab*:

21170lb

Maximum Operating Weight with Cab**:

22451lb

Note (2):

**Maximum Weight is based on steel tracks with rubber pads, counterweight, operator, full fuel tank, long stick, blade and no bucket.

Note (1):

*Minimum Weight is based on steel tracks, no counterweight, operator, full fuel tank, long stick, blade and no bucket.

Weight Increase from Minimum Configuration

Counterweight:

552lb

Steel Tracks with Pads:

728lb

Travel System

Maximum Traction Force - Low Speed:

19064lb

Maximum Traction Force - High Speed:

6497lb

Travel Speed - High:

3.1mile/h

Travel Speed - Low:

1.6mile/h

Ground Pressure - Maximum Weight:

6.4psi

Ground Pressure - Minimum Weight:

6psi

Gradeability - Maximum:

30 degrees

Service Refill Capacities

Hydraulic Tank:

14gal (US)

Cooling System:

2.6gal (US)

Engine Oil:

3gal (US)

Fuel Tank:

38gal (US)

Hydraulic System:

37gal (US)

Hydraulic System

Operating Pressure - Swing:

3336psi

Digging Force - Bucket:

17459lb

Operating Pressure - Travel:

4134psi

Operating Pressure - Equipment:

4134psi

Note:

Flow and pressure are not combinable. Under load, as flow rises pressure goes down.

Digging Force - Stick:

11060lb

Type:

Load Sensing Hydraulics with Variable Displacement Piston Pump

Pump Flow at 2,400 rpm:

62gal/min

Maximum Auxiliary Circuit - Secondary - Flow at Pump:

9gal/min

Maximum Auxiliary Circuit - Primary - Pressure at Pump:

4134psi

Maximum Auxiliary Circuit - Secondary - Pressure at Pump:

4134psi

Maximum Auxiliary Circuit - Primary - Flow at Pump:

35gal/min

Swing System

Machine Swing Speed:

10.6r/min

Blade

Height:

17in

Width - Standard:

97.2in

Width - Wide:

103.9in

Certification - Cab

Top Guard:

ISO 10262:1998 (Level I)

Roll Over Protective Structure (ROPS):

ISO 12117-2:2008

Tip Over Protective Structure (TOPS):

ISO 12117:1997

Sound

Average Exterior Sound Pressure (ISO 6395:2008):

99dB(A)

Operator Sound Pressure (ISO 6396:2008):

72dB(A)

Note:

European Union Directive "2000/14/EC"

Dimensions

Dig Depth:

205.2in

Dimensions - Standard Stick

Tail Swing without Counterweight:

70.9in

Stick Length:

98.4in

Boom In Reach:

83.3in

Maximum Reach:

303in

Dig Depth:

205.2in

Ground Clearance - Frame:

14in

O/A Track Width:

97.2in

Cab Height:

100in

Track Belt/Shoe Width:

17.7in

Maximum Blade Depth:

18.8in

Maximum Dump Clearance:

229.5in

Maximum Dig Height:

313.8in

Maximum Blade Height:

16.6in

Tail Swing - Standard Counterweight:

76.1in

O/A Undercarriage Length:

126in

Vertical Wall:

172.6in

Swing Bearing - Height:

28.9in

Maximum Reach - Ground Level:

298in

Overall Shipping Length - with Counterweight:

274.9in

Note (2):

**Boom Height when stick is pinned in working position with attachments.

Note (1):

*Boom Height when stick is pinned in transport position (if available) with no attachments.

Overall Shipping Length - without Counterweight:

269.7in

Height - Boom Transport - No Tools*:

100.4in

Height - Boom Working - With Tools**:

106.3in

Air Conditioning System

Air Conditioning:

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.0 kg of refrigerant which has a CO2 equivalent of 1.430 metric tonnes.

Engine

Note 1:

Advertised power is tested per the specified standard in effect at the time of manufacture.

Sustainability

Recyclability:

96%

Standard Equipment

guarding

- Roll Over Protective Structure (ROPS) ISO 12117-2:2008

- Top Guard ISO 10262:1998 (Level I)

engine

- Cat C3.3B Diesel Engine (U.S. EPA Tier 4 Final/EU Stage V) – Electronic Engine, Turbo, Diesel Particulate Filter (DPF)

- Automatic Engine Idle

- Automatic Engine Shutdown

- Automatic Swing Brake

- Automatic Two Speed Travel

- Fuel Water Separator with Indicator

- Radial Seal – Double Element Air Filter

- Extended Life Coolant, –37° C ( –37° F)

hydraulics

- Electronic Variable Displacement Piston Pump

- Load Sensing/Flow Sharing Hydraulics

- Power On Demand

- Hydraulic Temperature Monitoring

- Certified Accumulator

- HYDO Advanced Hydraulic Oil

operator environment

- TOPS – ISO 12117:1997

- ROPS ISO 12117-2:2008

- Stick Steer Mode

- Travel Cruise Control

- Control Pattern Changer

- Adjustable Wrist Rests

- Molded Footrests

- Removable, Washable Floor Mat

- Travel Pedals and Hand Levers

- Cat Key with Passcode Option

- HVAC with Automatic Temperature Control

- Hydraulic Lockout Controls

- Integrated Lower Front Window

- Assisted Front Window Overhead Storage

- Rear Window Emergency Exit

- Fabric, High Back, Suspension Seat

- Retractable Seat Belt (75 mm/3 in)

- Coat Hook

- Cup Holder

- LED Interior Light

- Literature Holder

- Mounting Bosses for Top and Front Guards

- 12V Power Socket

- Radio – Bluetooth, Auxiliary, Microphone, USB (charging only)

- Skylight

- Signaling/Warning Horn

- Cab and (left side) Boom Work Lights

- Utility Space for Mobile Phone

- Next Generation Color LCD Monitor (IP66)

– Jog Dial Interface

– Fuel Level and Coolant Temperature Gauges

– Maintenance and Machine Monitoring

– Performance and Machine Adjustments

– Numeric Security Code

– Multiple Languages

– Camera Ready (IP68 & IP69K)

– Hour Meter with Wake Up Switch

undercarriage

- Greased and Lubricated Track

- Tie Down Eyes on Track Frame

- Dozer Straight Blade

- Dozer Float

- Bolt-on, Reversible Wear Edge

boom, stick and linkages

- One Piece Boom (4300 mm/169.3 in)

- Front Shovel Capable – Pin-on/Manual Coupler/Hydraulic Coupler for Cat Tools (not available in all regions)

- Thumb Ready (not available in all regions)

electrical

- 12 Volt Electrical System

- 90 Ampere Alternator

- 900 CCA Maintenance Free Battery

- Battery Disconnect

- Ignition Key Stop Switch

- Travel Alarm

other

- Locks on External Enclosure Doors

- Lockable Fuel Cap

- Beacon Socket

- Rear Reflectors

Optional Equipment

operator environment

- Push to Start with Bluetooth® Key

- Air Suspension Heated Seat

- Rain Visor

- Next Generation Advanced Monitor (below are all included with Next Generation Advanced Monitor option)

– Touch Screen

– Site Reference System

– High Definition Camera Capable (IP68 & IP69K)

– Numeric Security Code

undercarriage

- Wide Dozer Blade

- Steel Tracks (450 mm/17.7 in wide)

- Wide Steel Tracks (600 mm/23.6 in)

- Steel Track with Rubber Pads

- Track Guides

boom, stick and linkages

- Long Stick (2500 mm/98.4 in)

- Attachments including Buckets, Augers and Hammers

- 2nd Auxiliary Hydraulic Lines

- Boom Lowering Check Valve

- Stick Lowering Check Valve

- Certified Lifting Eye

electrical

- Product Link Elite (regulations apply)

- Rearview Camera

- Rotating Beacon

guarding

- Top Guard ISO 10262:1998 (Level II)

- Front Guard (Mesh) ISO 10262:1998 (Level I)

- Front Guard (Heavy Duty) ISO 10262:1998 (Level II)

other

- Water Jacket Heater

- Refueling Pump