Fluid Analysis

The Importance of Fluid Analysis for General Equipment

Optimize Equipment Performance: Unlock the full potential of your machinery with our cutting-edge fluid analysis services. By monitoring the condition of your equipment’s fluids, you can proactively address issues before they escalate. This ensures optimal performance and minimizing downtime.

Reduce Costly Repairs: Stay ahead of maintenance needs and avoid unexpected breakdowns with our comprehensive fluid analysis. Our team of experts identifies potential problems early on. This allows you to take corrective action before they result in costly repairs.

Maximize Equipment Uptime: Keep your operations running smoothly with our fast and reliable fluid analysis process. With quick turnaround times and actionable insights, you can minimize downtime and maximize productivity on the job site.

Get comprehensive reports with expert analysis and tailored recommendations

Expert Analysis, Actionable Insights: Receive detailed reports with expert analysis and actionable recommendations tailored to your equipment’s specific needs. Our team of experienced analysts provides valuable insights to help you make informed decisions about maintenance as well as repairs.

Trusted Partner in Equipment Maintenance: With our advanced technology and industry expertise, we’re here to support you every step of the way in keeping your fleet in peak condition.

Drive Efficiency, Enhance Performance: By monitoring the health of your equipment’s fluids, you can drive efficiency, enhance performance, and extend the life of your valuable assets.

Empower equipment owners with invaluable data

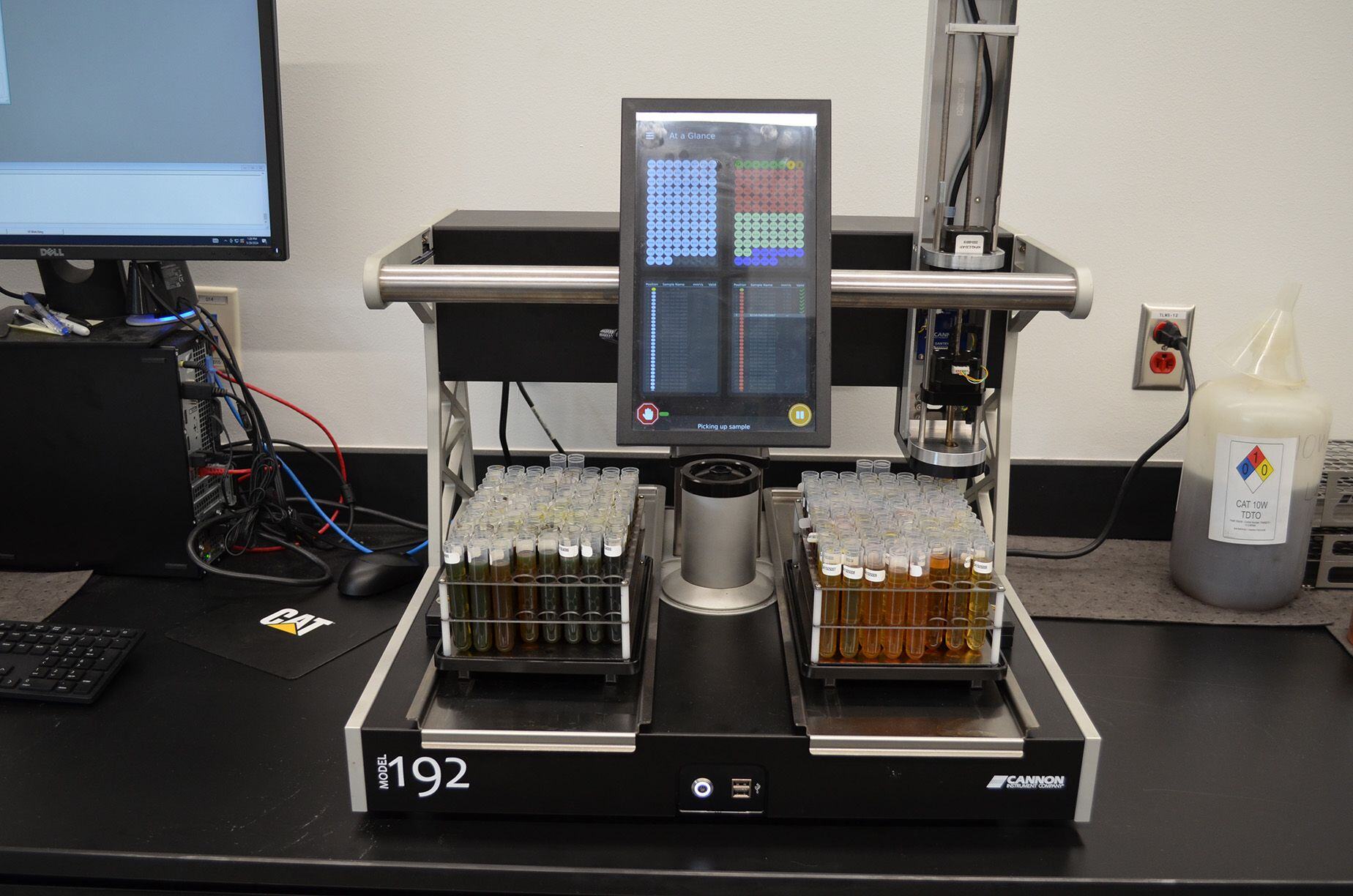

- Unboxing and Sorting: From all Cleveland Brothers locations, samples are conveniently boxed and sent to our lab, whether through mail or direct drop-off. We handle over 550 samples daily, ensuring both a streamlined and accurate analysis process for each fluid type.

- Water Check: Samples showing visual signs of water contamination undergo the crackle test, a rapid method to confirm water presence. This crucial step safeguards against corrosion as well as ensures equipment health.

- Dilution: For metal testing in oil or fuel samples, our efficient dilution process prepares samples for precise analysis, enhancing our ability to provide rapid, reliable results.

- FTIR: Infrared lasers measure soot, as well as oxidation, nitration, and sulfation levels, offering critical insights into oil condition and detecting potential water contamination.

- Metals: Elemental analysis using plasma emission spectroscopy detects specific elements and concentrations, aiding in early detection of both wear and contamination.

- Particle Count: Specialized light beam technology meticulously counts and measures particle size, preserving fluid integrity and optimizing equipment performance.

- Viscosity: Precise measurement of viscosity ensures optimal lubrication quality and equipment health, enhancing performance and longevity.

- Fuel Dilution: Rigorous testing detects excessive fuel contamination, maintaining both oil integrity and efficiency in diesel engines.

- Sample Interpretation: Receive a user-friendly report with expert analysis and recommendations for proactive maintenance. This empowers you to make informed decisions about your equipment’s health.