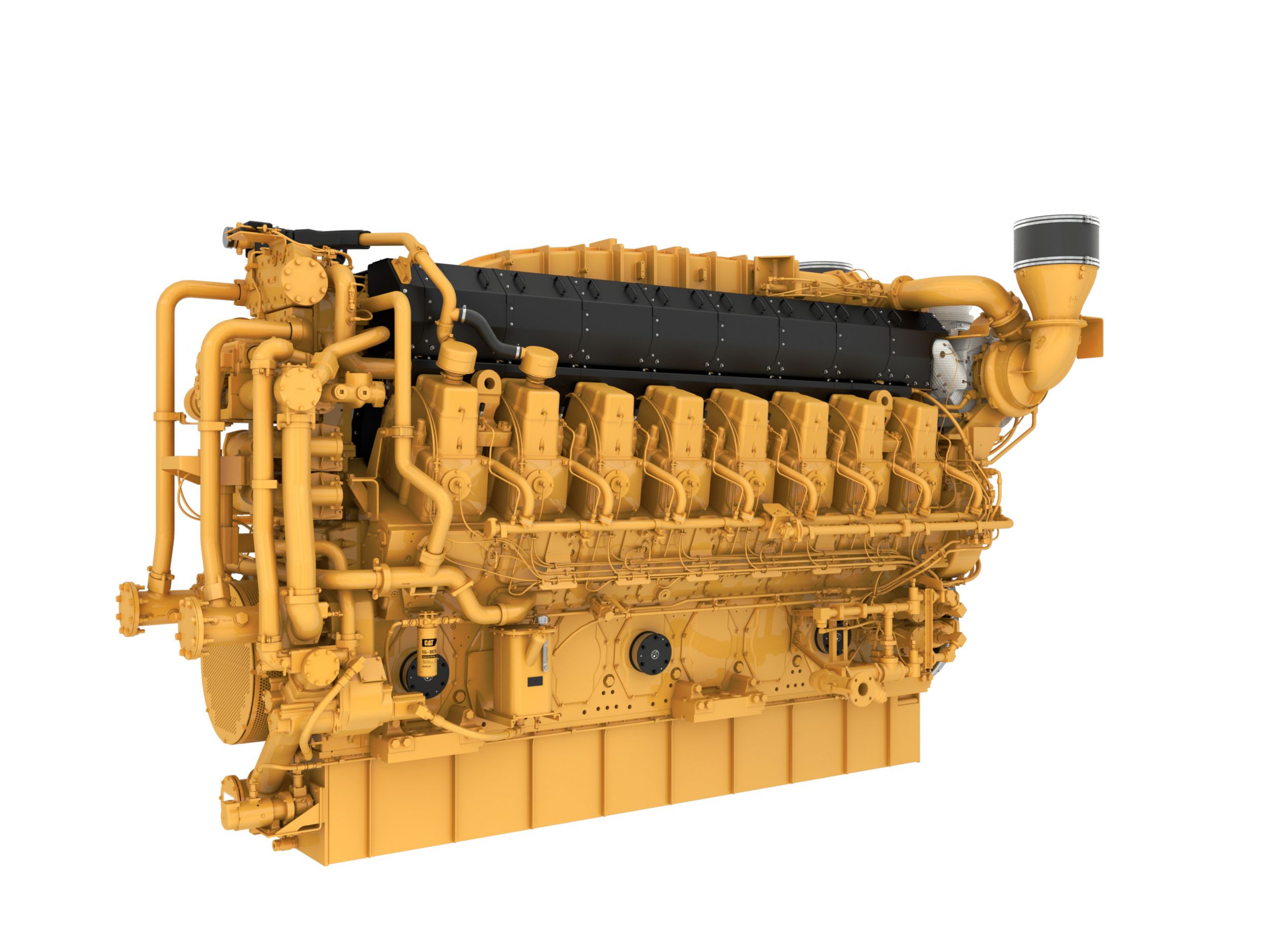

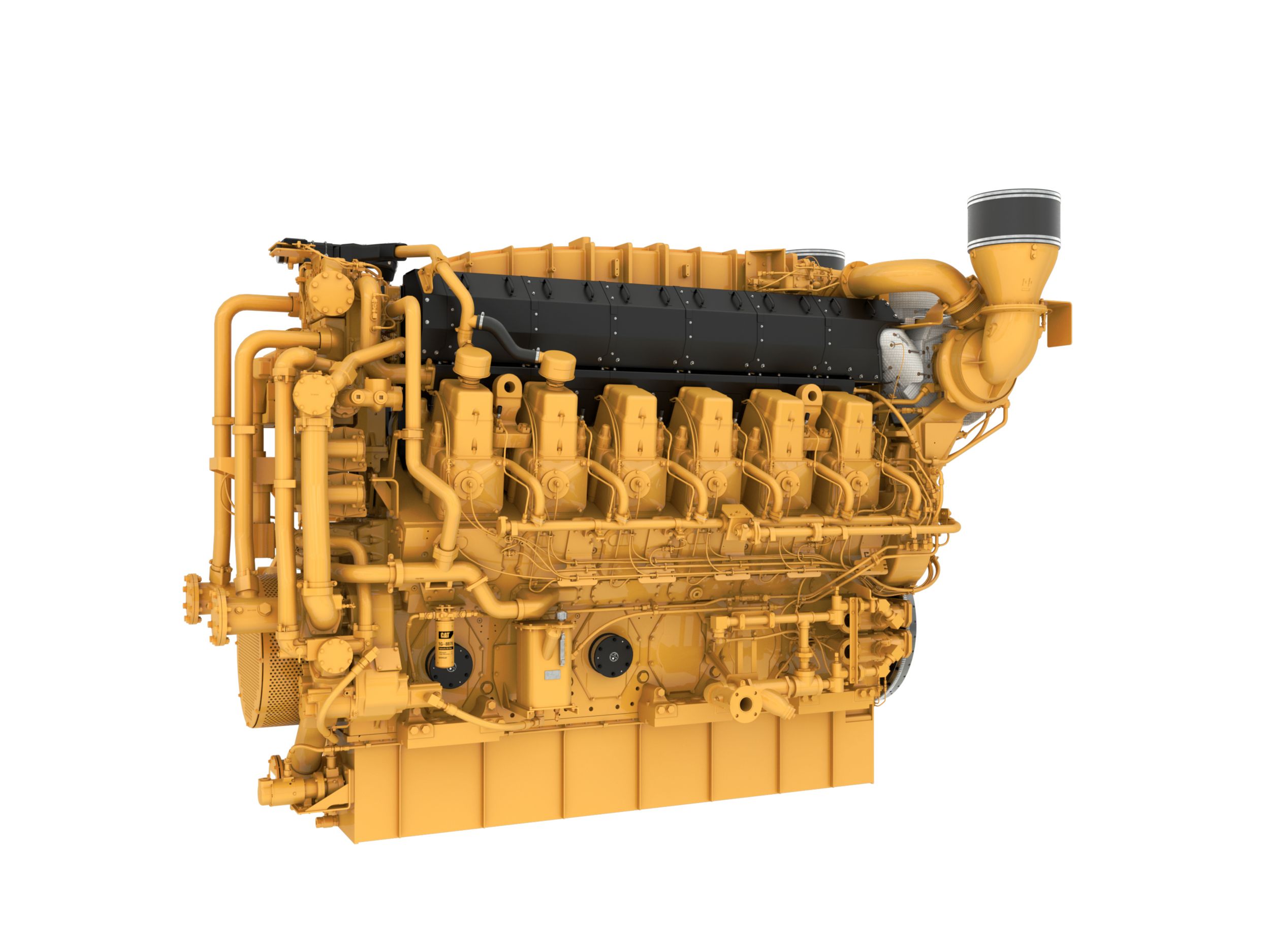

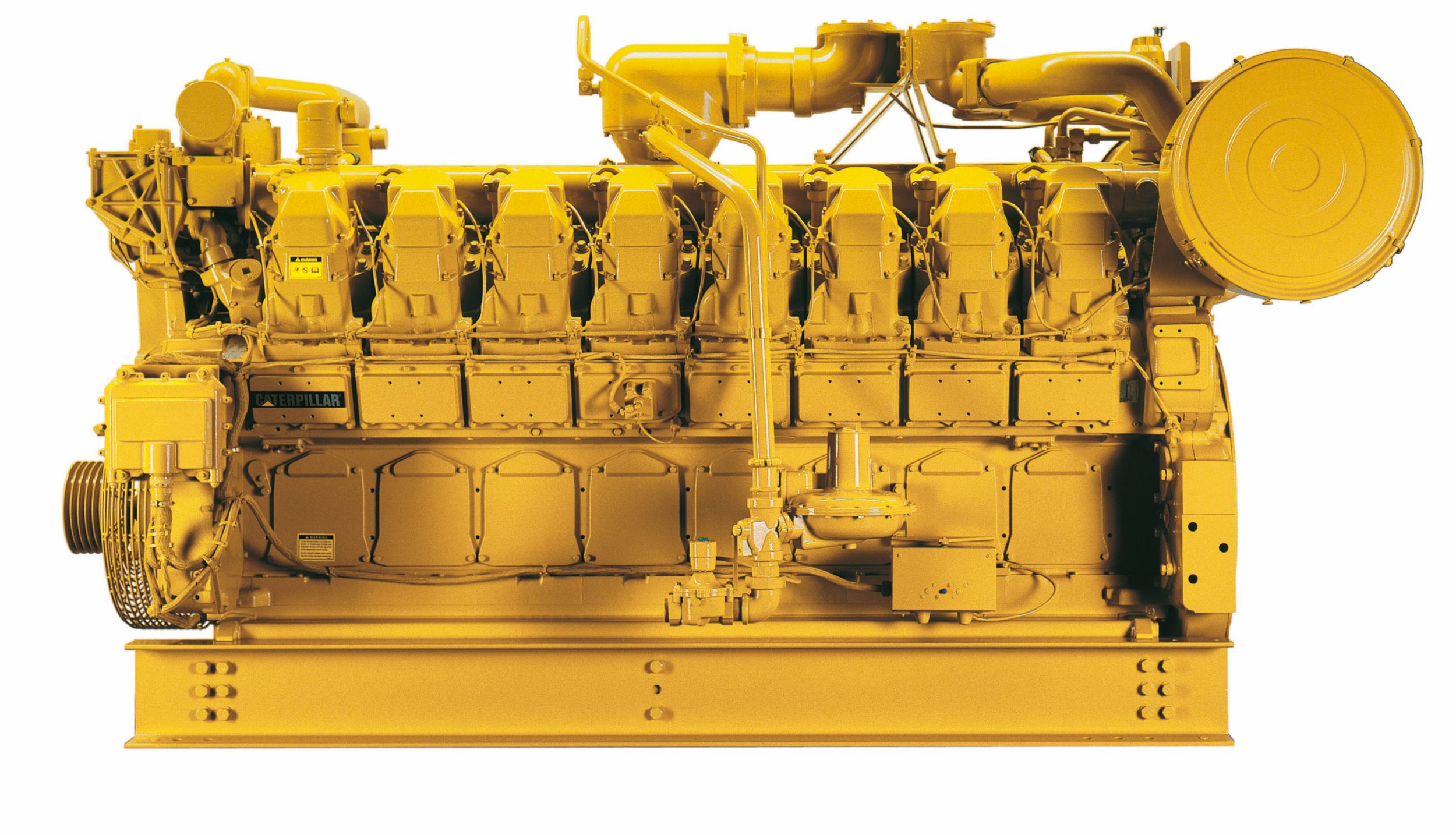

G3612 A4 Gas Compression Engine

- new - Products

- G3612 A4 Gas Compression Engine

At a glance data:

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

Overview

G3600 ADEM™4 engines provide a wide range of power options to fit your gas compression application. G3600 ADEM™4 engines bring the highest uptime in the industry and long operating intervals between overhaul. Operators that use G3600 ADEM™4 engines in their fleet enjoy virtually no unscheduled downtime, the right power for their application, the lowest operating costs, and emissions compliance. Ideal applications for G3600 ADEM™4 engines include centralized gathering stations, gas processing, transmissions, and storage applications. Cat G3612 ADEM™4 Gen 1 gas engine with ratings: 2796 bkW (3750 bhp) @ 1000 rpm and Cat G3612 ADEM™4 Gen 2 gas engine with ratings: 2015 bKW (2750bhp) @ 1000 rpm. NSPS site compliant capable.

Engine Specifications

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

Compression Ratio:

Gen 1 (9.2:1) Gen 2 (7:6:1)

Aspiration:

Turbocharged-Aftercooled

Rotation from Flywheel End:

Counterclockwise

Flywheel Teeth:

255

Weight - Dry:

58500.0lb

Oil Change Interval:

5000 hours

Ignition, Protection:

ADEM™4

Stroke:

11.8in

Bore:

11.8in

Capacity for Liquids

Cooling System:

194.0gal (US)

Lube Oil System - Refill:

272.0gal (US)

Standard Equipment

air inlet system

- Air cleaner — standard duty Inlet air adapter

control system

- A4 control system — provides electronic governing integrated with air/fuel ratio control and individual cylinder ignition timing control

cooling system

- Jacket water pump

- Jacket water thermostats and housing

- Aftercooler pump

- Aftercooler water thermostats and housing

- Two-stage aftercooler

exhaust system

- Dry wrapped exhaust manifolds

- Vertical outlet adapter

flywheel & flywheel housing

- SAE standard rotation

fuel system

- Gas admission valves -- electronically controlled fuel supply pressure

ignition system

- A4 control system — senses individual cylinder detonation and controls individual cylinder timing

lube system

- Crankcase breathers — top mounted

- Oil cooler

- Oil filter

- Oil pan drain valve

mounting system

- Engine mounting feet (six total)

protection system

- Electronic shutoff system with purge cycle

- Crankcase explosion relief valves

- Gas shutoff valve

starting system

- Air starting system

general

- Paint — Cat yellow

- Vibration dampers

Optional Equipment

air inlet system

- Heavy-duty air cleaner with precleaners and rain protection

charging system

- 35 Amp & 65 Amp chargin alternators - CSA approved

exhaust system

- Flexible bellows adapters

- Exhaust expander

- Weld flanges

fuel system

- Fuel filter

- Gas pressure regulator

- Flexible connection

- Low energy fuel system

- Corrosive gas fuel system

instrumentation

- Remote data monitoring and speed control

- Compatible with Cat Electronic Technician (ET) and Data View

- LCD display panel

- Color HMI display

- Modbus and Ethernet capable

lube system

- Air or electric motor-driven prelube

- Duplex oil filter

- RH service

- Lube oil makeup system

mounting system

- Mounting plates (set of six)

power take-offs

- Front stub shafts

starting system

- Air pressure reducing valve

- Natural gas starting system

general

- Engine barring device

- Damper guard

G3606 A4 Gas Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

G3616 A4 Gas Compression Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

G3608 A4 Gas Compression Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

Similar Products

G3612 A4 Gas Compression Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

CG137-8 Gas Compression Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP

G3516 LE Gas Engine

Maximum Rating:

4125BHP

Emissions:

NSPS Site Compliant Capable

Displacement:

15528.0in³

Minimum Rating:

3750BHP