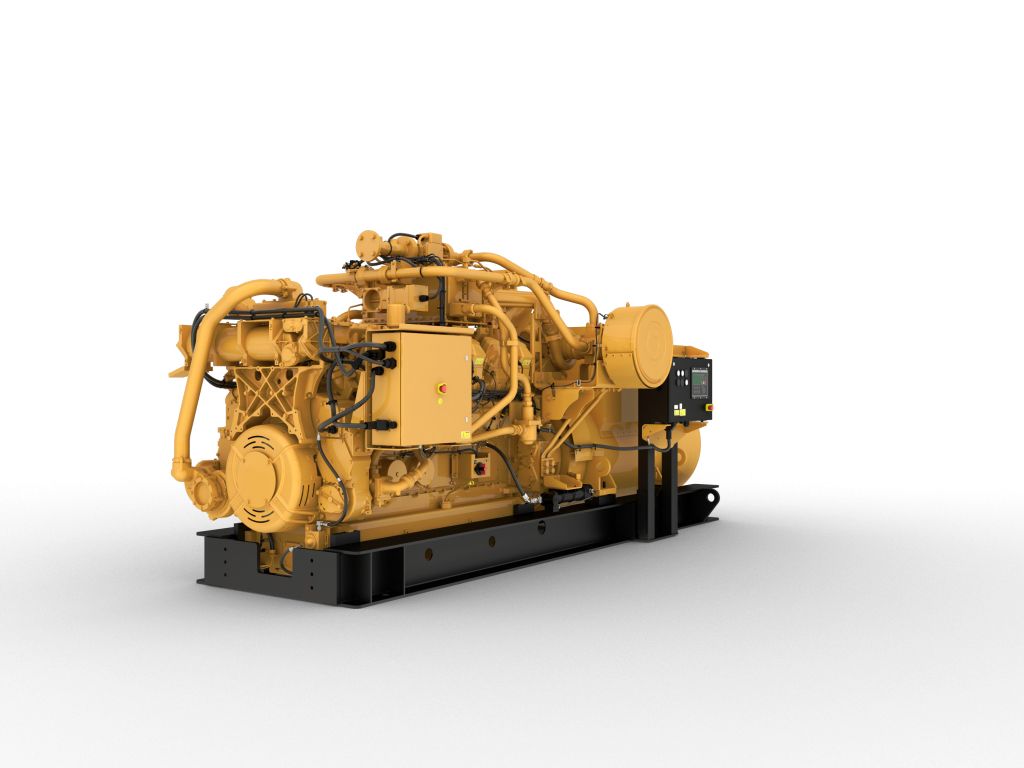

G3512

- new - Products

- G3512

At a glance data:

Overview

Production of oil and gas in remote oilfields can be a challenge when utility power is not available. The Caterpillar product line of oilfield gas generator sets provides the ideal solutions for this challenge. Engines are designed to run on low to no-cost well site gas without sacrificing on performance. These generator sets allow customers to significantly reduce fuel cost and avoid the expense and logistics of diesel fuel deliveries. Plus, they are designed to withstand the harsh conditions in the oilfield and feature a heavy-duty construction ideal for loading and unloading operations. Cat generator sets are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty.Ratings: 1095 bkW (1468 bhp) @1800 rpm.

Engine Specifications

Dimensions

Engine Specifications

Standard Equipment

air inlet system

- Air cleaner, intermediate duty, with service indicator and air filter differential pressure sensors

cooling system

- Jacket water outlet- right hand flange connection

- Jacket water pump, gear driven, centrifugal, non - priming

exhaust system

- Dry exhaust manifold

fuel system

- 10-35 kPag gas supply

instrumentation

- EMCP 4.4

- ADEM™4

lubrication system

- Crankcase breather - top mounted

- Prelube pump

- Simplex oil filter

- Standard Oil Pan

Optional Equipment

air inlet system

- Pre-cleaners

charging alternator

- Charging alternator 24V, 35A

connections

- Left hand flanged jacket water connection

exhaust system

- Exhaust weld flange

fuel system

- Gas train

lubrication system

- Electric prelube

- Air prelube

- Oil level regulator

- Oil drain

starting system

- Barring group

- Right hand air starter

Similar Products

G3520

CG137-12 Oilfield Gas Generator Set