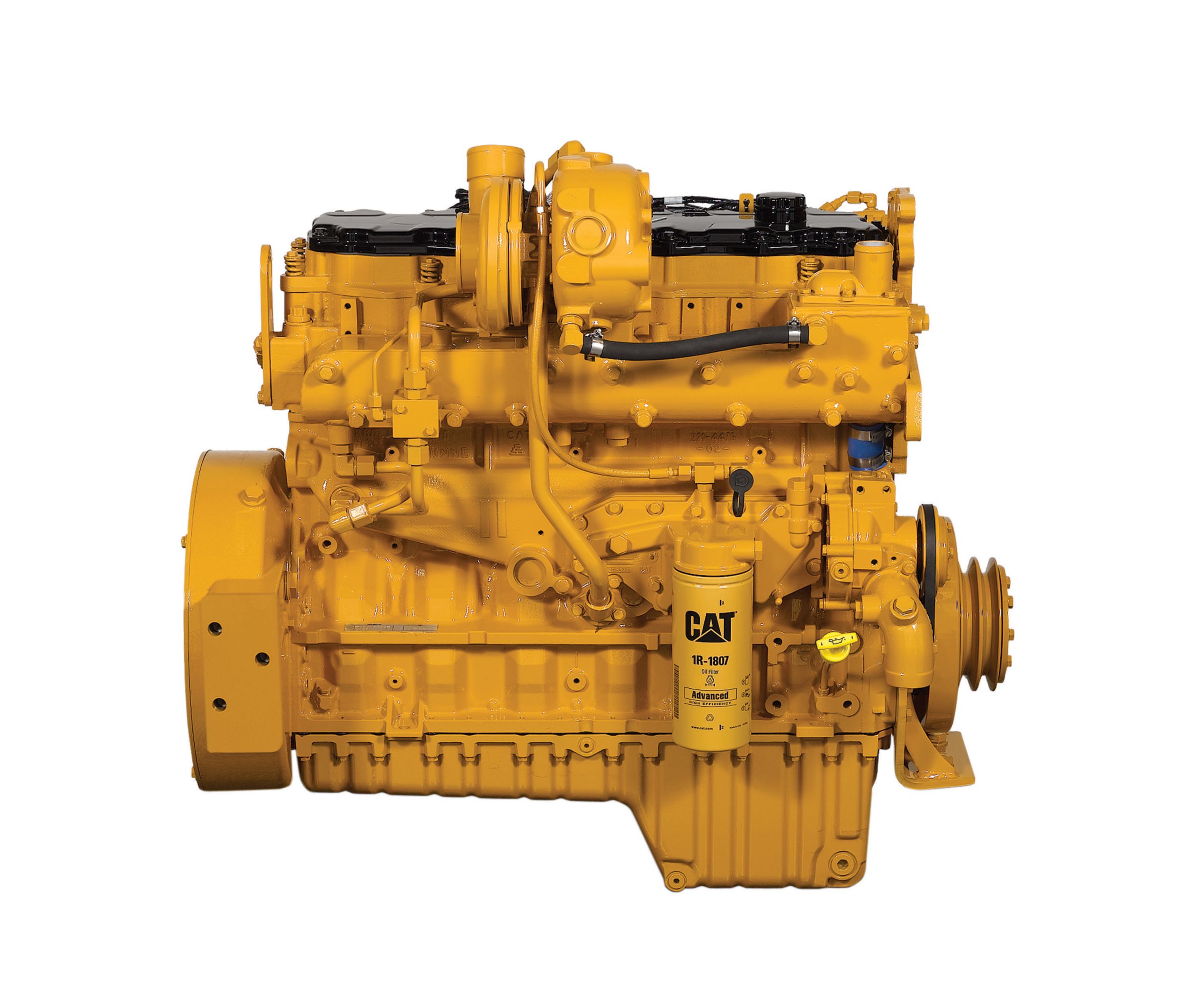

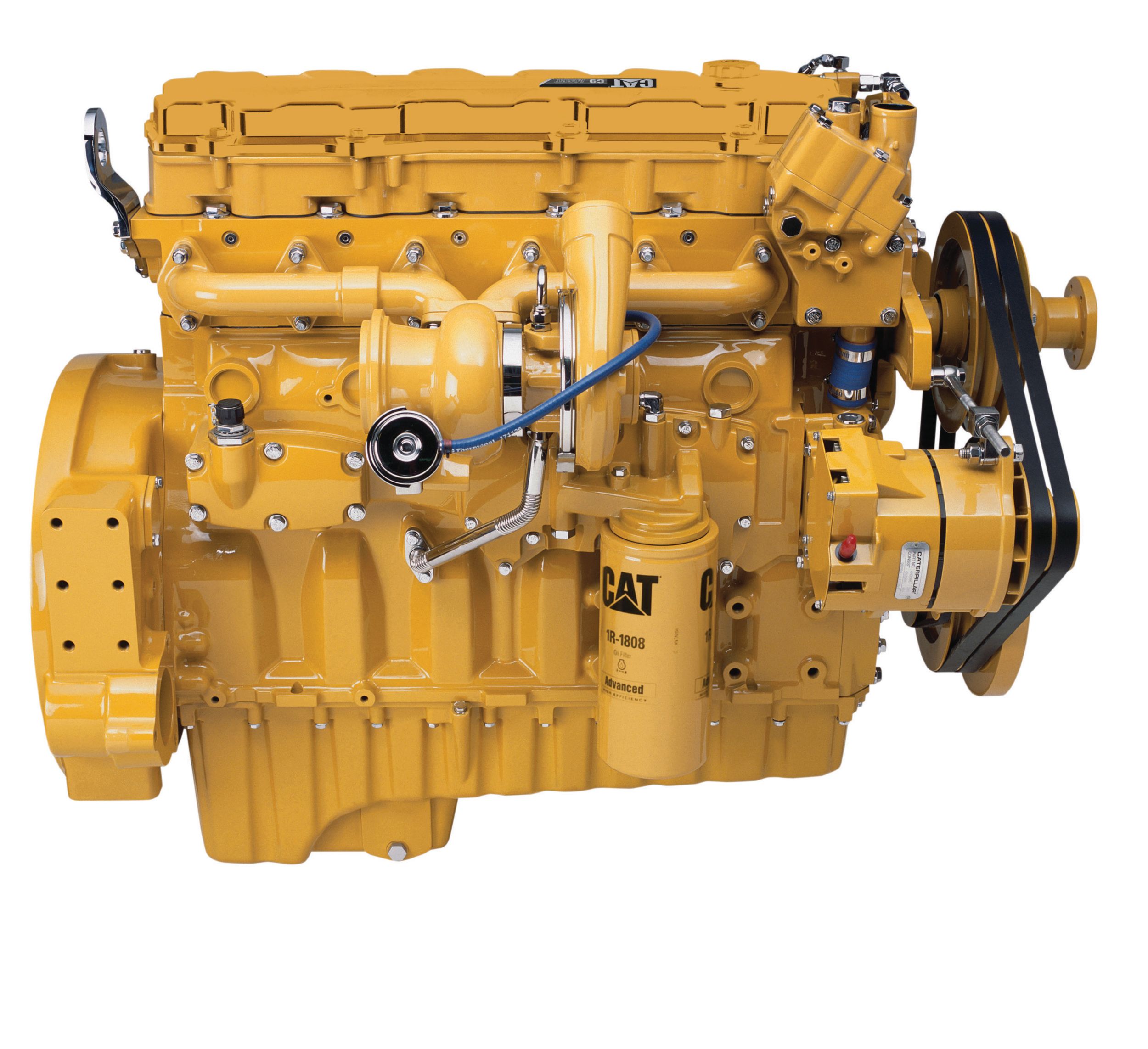

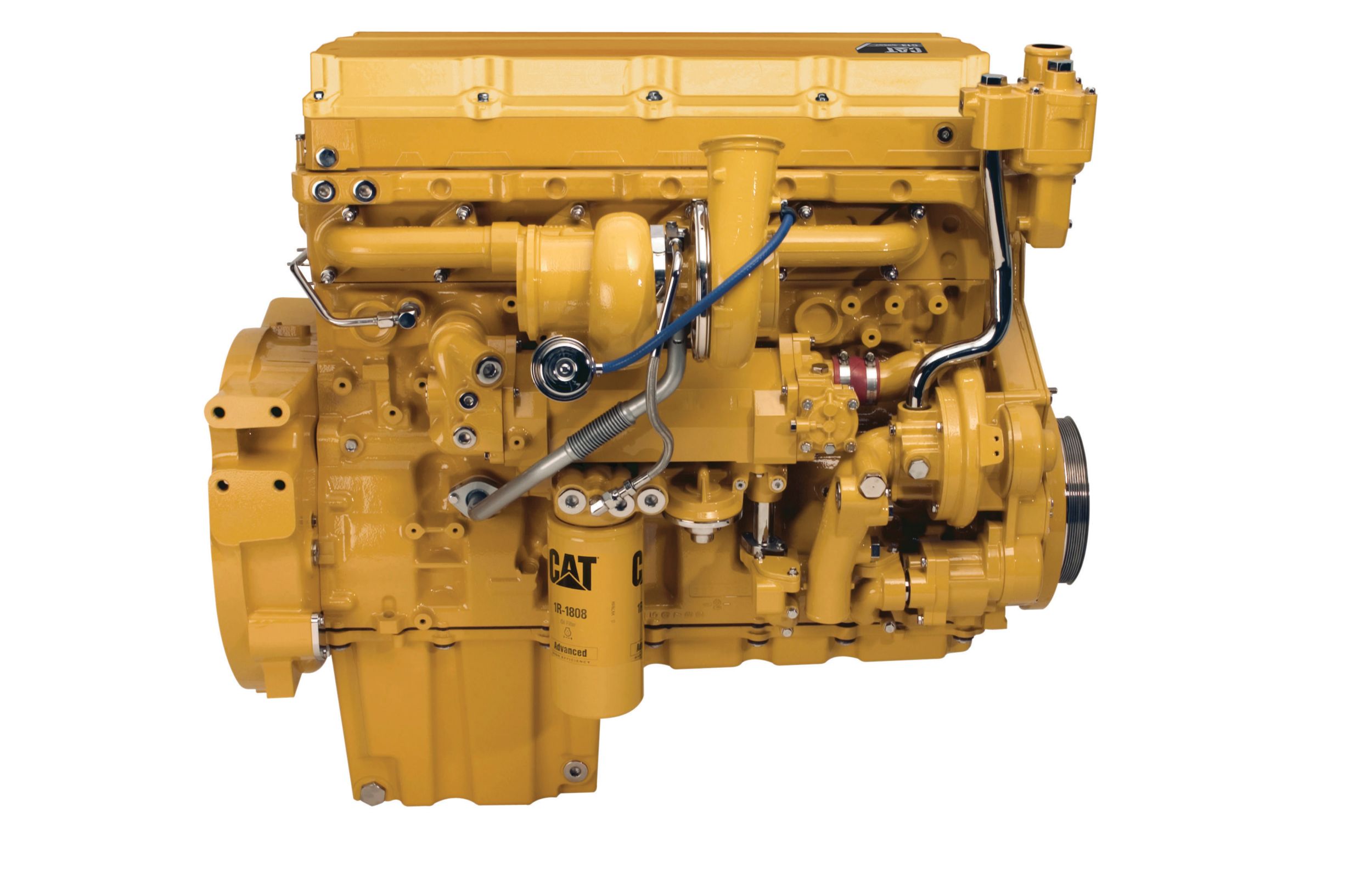

C15 ACERT™ Dry Manifold Engine

- new - Products

- C15 ACERT™ Dry Manifold Engine

At a glance data:

Overview

Cat C15 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C15 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C15 ACERT engines include workover rigs, pump skids, nitrogen units, acidizing units, cementing units, blenders, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. C15 ACERT engines, with ratings: 328-444 bkW (440-595 bhp) @ 1800-2100 rpm, meet China Stage II, U.S. EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards. They are available using U.S. EPA and EU Flexibility, and for other regulated and non-regulated areas.

General Specifications

Emissions

Dimensions

Capacity for Liquids

Standard Equipment

air inlet system

- Single turbocharger, mid-mounted, inlet 152.4 mm (6 in), hose connection

control system

- Electronic governing, PTO speed control

- Programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle and TEL

- Electronic diagnostics and fault logging

- Engine monitoring and protection system (speed, temperature, pressure)

- J1939 Broadcast (diagnostic, engine status, and control)

cooling system

- Thermostats and housing — outlet vertical

- Jacket water pump — gear-driven, centrifugal, RH

- RH front water pump inlet

- All plugs/fittings are STOR for lines gp water

exhaust system

- Exhaust manifold — dry

- Front turbo exhaust

- Full marmon connection, maximum load 10 kg for direct connection to turbo

flywheels and flywheel housings

- See Mandatory Options

fuel system

- MEUI system

- Fuel filter, secondary, mid-mount (LH 2 micron high performance)

- Fuel transfer pump, LH front

- Fuel priming pump, LH mid-mount

- Fuel sample valve, mounted on fuel filter base

lube system

- Crankcase breather — rear valve cover

- Oil cooler — RH

- Oil filter — RH

- Oil pan — front sump

- Oil filler — LH front

- Oil dipstick — LH front

- Oil pump

- Oil valve sampling — on oil filter base

mounting system

- Front support (shipping only)

power take-offs

- Crankshaft pulley, 203.2 mm (8 in), 3 grooves 292.1 mm (11.5 in) 1 groove, all 15.9 mm (.63 in) width

- Hydraulic pump drive, SAE A, 11 tooth

general

- Vibration damper

- Paint — Cat yellow

- Lifting eyes

- Automatic variable timing, electronic

- Electronic installation kit 70-pin connector (connectors, pins, sockets)

- Literature group owner and operator

mandatory options

- Throttle position sensor

- Exhaust system — front or rear

- Flywheel housing or rear PTO

- Primary filter/water separator

Optional Equipment

transmission arrangement

- Transmission cooler

- Tool set

air compressor

- Air chambers

- Air compressor governor

air inlet system

- Air cleaners

- Precleaners

- Air lines

- Air inlet gasket

charging system

- Charging alternators

- Alternator mountings

- Alternator wiring

- Circuit breaker mountings

- Alternator belt guard

cooling system

- Radiator — installed

- Radiator — ship loose

- Fan drive f/u/w Caterpillar installed radiator

- Fan drives for customer-supplied radiators

- Fan height instructions

- Vee belts for customer-supplied radiators

- Aftercooler lines f/u/w Caterpillar installed radiator

- Rear-facing exhaust

- Aftercooler lines

- Suction fan adapters — attaches fan to fan pulley

- Blower fan adapter — attaches fan to fan pulley

- Blower fan

- Suction fan

- Fan belt tightener

- Coolant level sensor

- Dry charge coolant conditioners

- Dry charge coolant conditioner element

exhaust system

- Turbo exhaust connection

- Flexible fitting

- Elbows

- Flanges

- Dry elbow

C7 ACERT™ Water-Cooled Manifold Engine

C7 ACERT™ Hazardous Location Engine

C7 ACERT™ Dry Manifold Engine

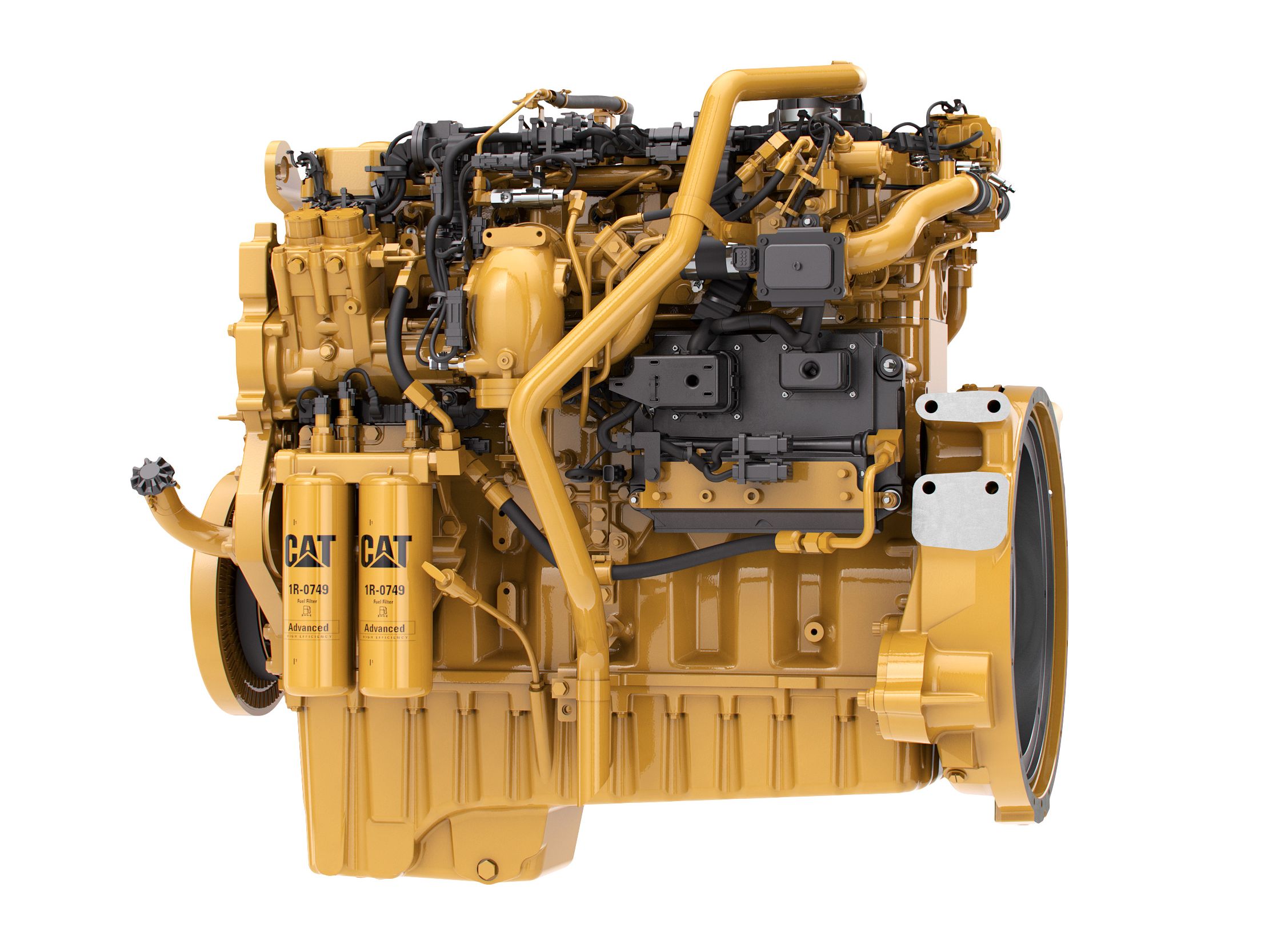

C9 ACERT™ Dry Manifold Engine

C9 ACERT™ Water Cooled Manifold Engine

C11 ACERT™ Dry Manifold Engine

C9 ACERT™ Hazardous Location Engine

C13 ACERT™ Dry Manifold Petroleum Engine

Similar Products

C9.3 ACERT™ Tier 4 Final Engine

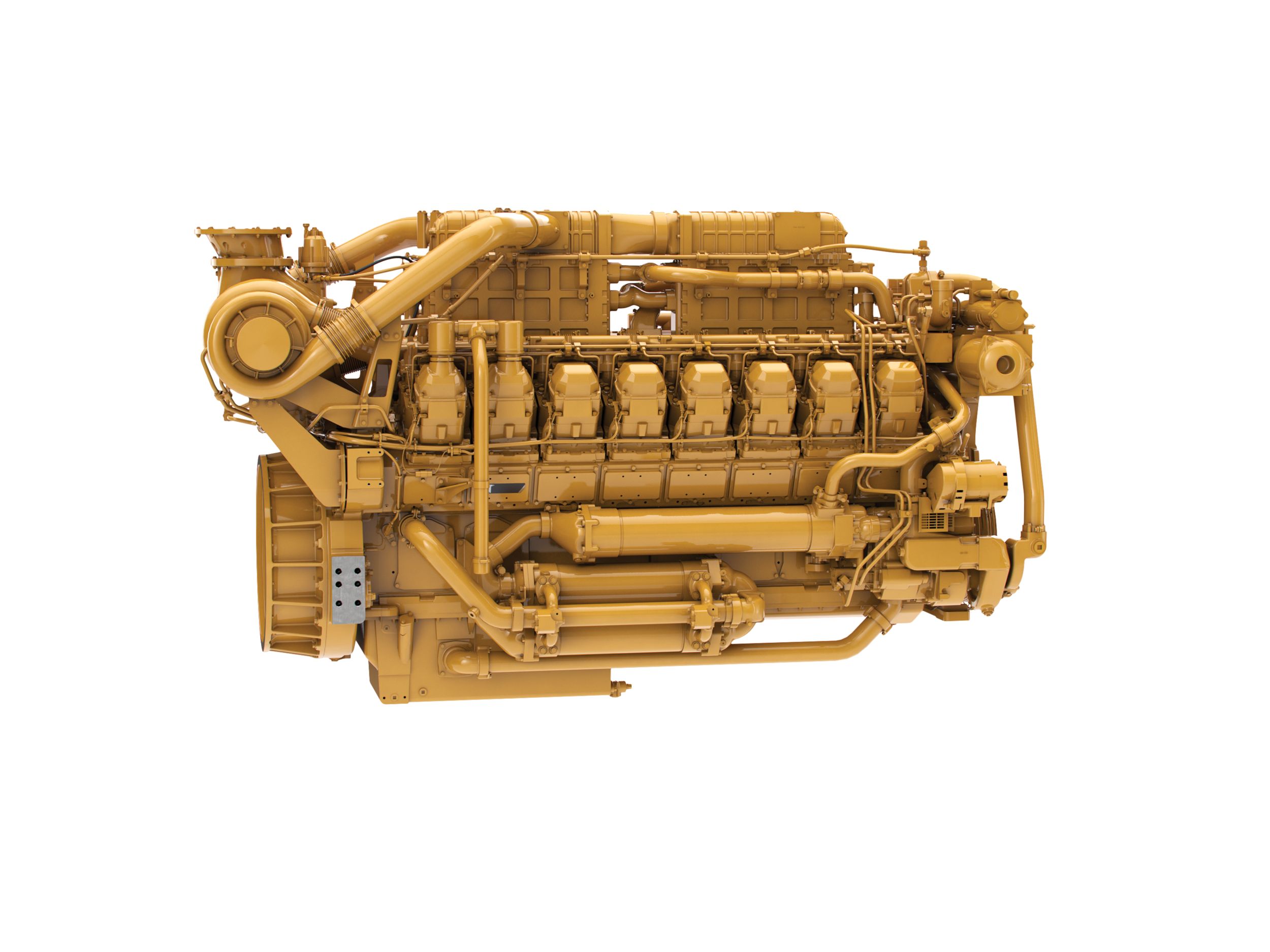

3516C (HD) Well Stimulation Engine